Manufacturing Capabilities

- 3D printing rapid prototyping (FFF)

- CNC routing and small scale machining

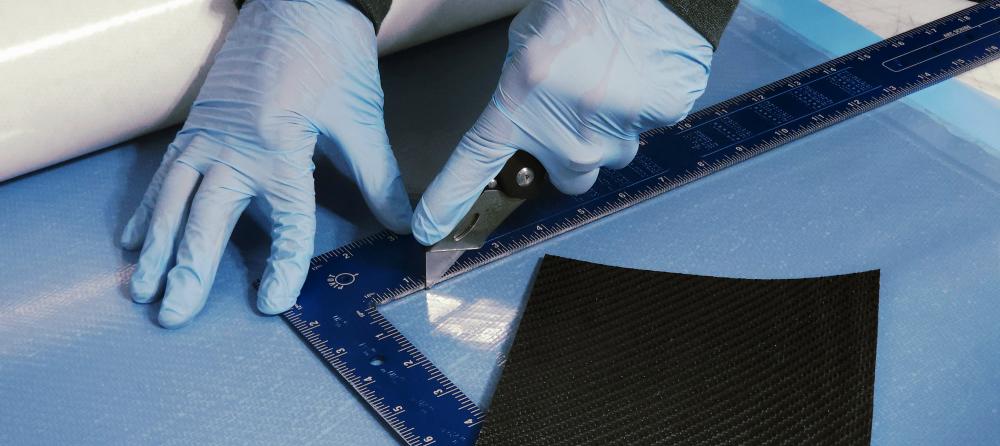

- VARTM composite fabrication

- Autoclave composite fabrication

- Hot press forming

- 12 in × 12 in heated platen up to 500 °F

- 8 in × 12 in heated platen up to 850 °F

Resin Physicals

- Density / specific gravity — ASTM D792, ASTM D1481

- Viscometry — ASTM D2196

-

Resin solids / volatile content — ASTM D3530, ASTM D3529

- Gel time — ASTM D3532, ASTM D2471

- Viscoelastic properties (DMA) — ASTM D7028, ASTM E1640

Mechanical Properties

- Tensile properties — ASTM D3039, ASTM D638

- Flexural properties — ASTM D790

-

Short beam shear — ASTM D2344

- Compression (CLC) — ASTM D6641

- Tensile shear, single lap joint — ASTM D1002

- Climbing drum peel — ASTM D1781

Flammability Testing

- FAR 25.853 — 12 s / 60 s vertical, horizontal, 45°

- UL 94

-

ASTM D635, ASTM D3801