Advanced Adhesive Technologies and Specialty Products & Compounds for Critical Applications

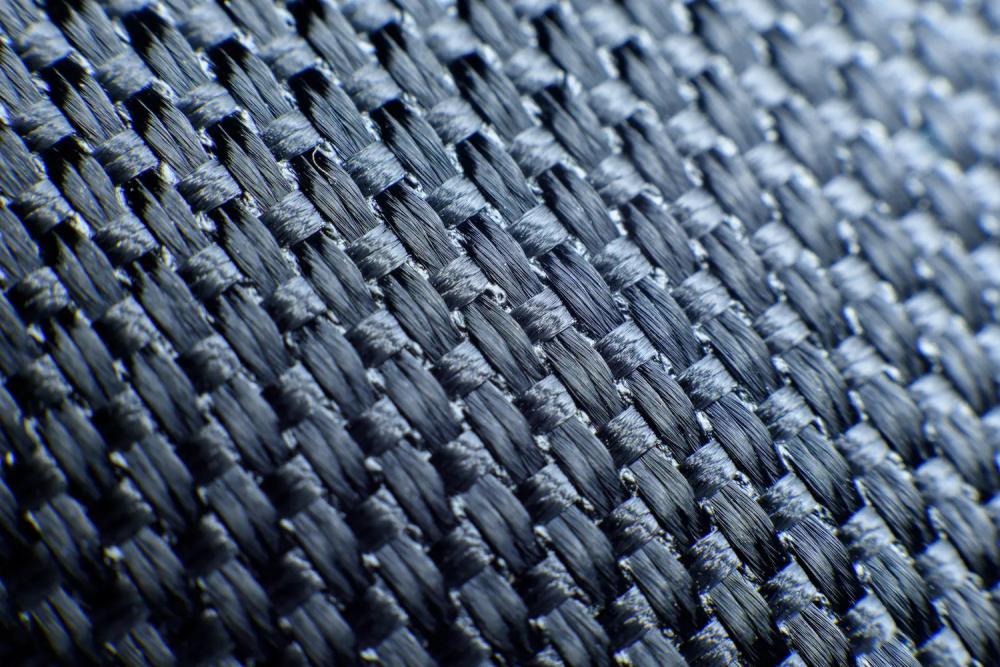

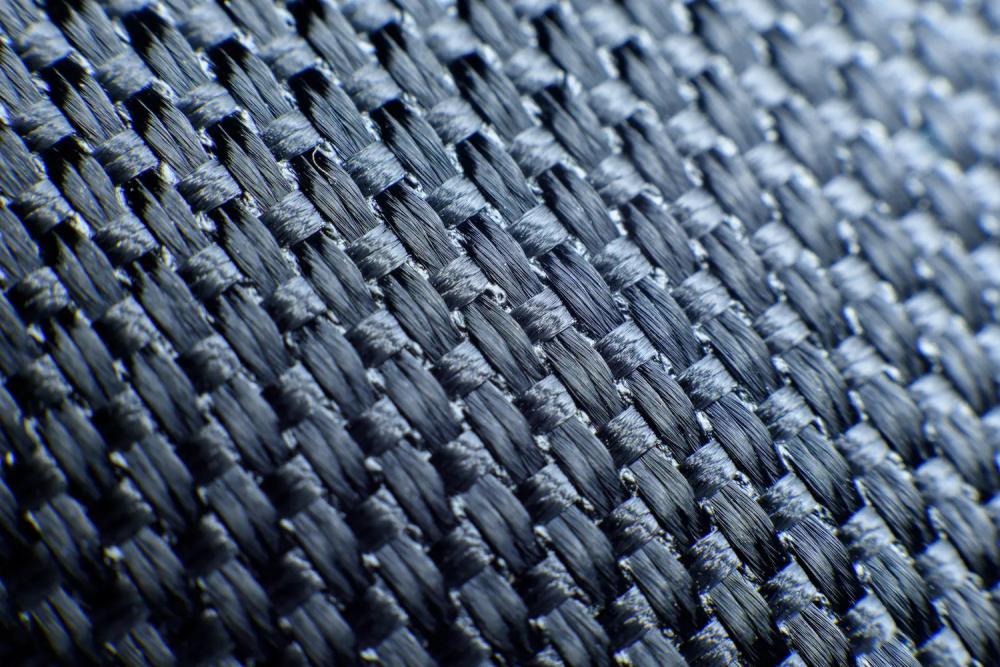

Makobond specialty products combine advanced chemistry with engineering collaboration to deliver reliable bonding, potting, and structural solutions across aerospace, defense, automotive, marine, sports, medical, and industrial applications. Whether you need an expanding core splice adhesive for honeycomb core bonding, a high-temperature structural adhesive film, or a vibration-damping ply for composite layups, each formulation is engineered for consistent adhesion, thermal stability, and durability in demanding environments.

Designed for co-curing into complex composite assemblies, Makobond materials enable lighter structures, stronger bonds, and more efficient production cycles while meeting strict industrial and aerospace specifications. Supported by responsive technical expertise and custom formulation capabilities, our specialty compounds help manufacturers innovate, optimize productivity, and achieve performance that cannot fail.

KEY FEATURES

High Bond

Integrity

Uniform bondline control and exceptional peel strength for predictable structural performance.

Thermal and

Chemical Resistance

Built to withstand demanding temperature variations, vibration, and environmental exposure.

Lightweight and

FST Compliant

Optimized strength-to-weight ratios and full compliance with flame, smoke, and toxicity (FST) standards.

Process Flexibility

Compatible with standard composite cure cycles and variable-temperature processing environments.

Reliable Quality

and Support

Backed by MAKO’s in-house testing, data validation, and engineering partnership for consistent results.

Speak with our Technical Sales Team

SPECIALTY PRODUCTS

Lightweight Syntactic Core Splicing Adhesive Film

Makobond AF-1070 is a lightweight, single-component syntactic film adhesive engineered for precision core splicing and honeycomb edge bonding applications. Its co-curable formulation provides smooth, controlled flow, excellent core wet-out, and uniform adhesion across composite sandwich structures, ensuring optimal strength-to-weight performance. Designed for compatibility with most epoxy prepreg systems, AF-1070 offers reliable handling and consistent results, even in demanding aerospace and industrial environments. Its advanced formulation delivers exceptional bonding strength while remaining FST compliant, making it suitable for regulated aviation applications where managing flame, smoke, and toxicity are critical. With its ease of processing and superior performance characteristics, AF-1070 is an ideal choice for manufacturers seeking a high-quality adhesive solution that meets the rigorous demands of modern composite construction.

Lightweight, Advanced Damping Adhesive Film

Makobond AF-1025 is a highly engineered, lightweight damping adhesive film designed for advanced noise and vibration mitigation in a variety of applications. This adhesive film integrates a unique blend of polymeric materials that confer long-lasting flexibility, enabling it to maintain performance under dynamic mechanical loads and thermal cycling. Its superior thermal expansion absorption properties make it ideal for use in environments subject to fluctuating temperatures, ensuring consistent bonding and structural integrity. The film exhibits robust resistance to a wide spectrum of chemicals, solvents, and environmental agents, extending its durability and performance life in challenging conditions. This advanced damping adhesive film excels in noise reduction by effectively dissipating vibrational energy, reducing structural-borne noise, and enhancing acoustic comfort across a range of environmental settings. Its versatility and technical sophistication make Makobond AF-1025 an optimal solution for industries requiring high-performance adhesive solutions with multifunctional capabilities. Makobond AF-1025 powered by Kraibon®.

| ID | Name | Description | Tg or Service | Common Types | Cure Options | Lead Time |

|---|---|---|---|---|---|---|

| AF-1070 | MAKOBOND® AF-1070 - Lightweight Syntactic Core Splicing Film Adhesive | Makobond AF-1070 is a low-density Core Splice that is ideal for critical applications like filling gaps, core splicing, and reinforcing honeycomb structures. With a cure range of 220°F to 290°F, it adds minimal weight while providing strong structural support. Available in flame-retardant versions, AF-1070 is perfect for automotive racing, sporting goods, and composite components. | 290 °F (143 °C) | 0.800 psf 0.150 in (3.8 mm) thickness 3-3.5 Expansion Ratio | 284F (140C), 35min 248F (120C), 60min 212F (100C), 90min | 2-3 Weeks ARO |

| AF-1025 | MAKOBOND® AF-1025 - Lightweight, Advanced Damping Film Adhesive | Makobond AF-1025 is a lightweight, high-performance damping adhesive film engineered to reduce noise and vibration. Powered by Kraibon®, it offers long-lasting flexibility, thermal stability, and chemical resistance, ensuring consistent performance under dynamic loads and fluctuating temperatures. Ideal for industries requiring durable, multifunctional adhesive solutions. | 300 °F (150 °C) | 0.020 psf (100 gsm) on Spunwoven Polyester Carrier 0.060 psf (300 gsm) prelaminated on Aramid Fabric |

250 F (120C), 60 min 275F (135C), 30 min 300F (150C), 10 min | 2-3 Weeks ARO |

*The data provided is for informational purposes only and does not constitute a warranty. Users must verify suitability through testing. Refer to the SOS and label for safe handling instructions. This product is for industrial/commercial use, handled by trained personnel.